Rolling Stock

Bombardier Transportation Projects UK

NLR/ELR Class 378 & GAUTRAIN class 301

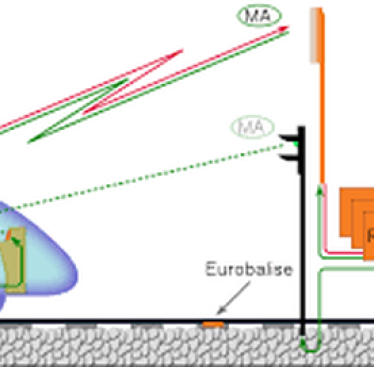

- Lead the integration of an ATP system onto the train

- Worked with the supply chain on behalf of the client to design, develop and integrate the Driver Only Operation (DOO) and Saloon CCTV systems

- Designed and tested all electrical train control functions

LERL Class 379 EMU

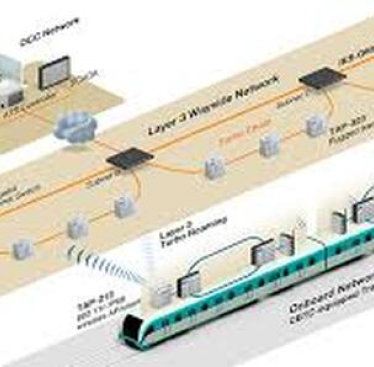

- Ikube acted as the principal systems integrator for the design and development of the most technologically advanced DOO & Saloon CCTV system of its generation, for UK rolling stock. The system was fully integrated onto the TCMS IP network

Aventra Platform & Crossrail Class 345 EMU

- Ikube provided Engineering management services to lead a large team of multi-disciplined engineers (Systems, Software, Test, SWQA) for the train control and information systems function.

- Defined strategic improvement initiatives to transform the engineering processes, tools and methodologies for system and software development on their next generation EMU product platform AVENTRA

Alstom Transportation UK

WCML (Pendolino) Class 390 EMU

- Provided services for the Type testing and Commissioning of all train borne electrical subsystem’s, producing test specifications and test reports

- Led the reliability growth improvements for HVAC and CCTV

- Designed and commissioned an overhaul facility for the saloon and cab HVAC modules with an annual cost saving of £2m to the business

- Introduced a pre-summer and pre-winter check to supplement the ongoing maintenance regime

- Conducted Technical fault finding and root cause failure investigations and analysis for all electrical subsystems including the Train Monitoring System (TMS)

- Producing Request for Trials (RfT’s) and Field Modification Instructions (FMI’s) to support the reliability growth initiative

Signaling Solutions

London Underground

SRR Signalling Upgrade - Communication Based Train Control (4 Lines Modernisation)

- Acted as the railway Systems Integrator for the 4LM programme. Conducting feasibility studies and impact assessments for a diverse range of requirements introduced by the programme sponsor.

- Produced the interface and architecture diagrams for the migration of the Legacy Signalling Control, Train Describer/CIS/GSM-R and LVAC subsystems to an integrated CBTC controlled signalling system across fourteen Signalling Migration Areas

- Worked with the data provided by LU track to identify the sections of track requiring a Vmax uplift to support the End State operational service timetable of 32TPH in the central section of the SSR network (Peak Time)

Hitachi Information Control Systems

Thameslink Traffic Management System

- Led system testing, commissioning, and system verification activities for the HICSE TMS project.

- Performed integrated sub-system testing on the Traffic Management System, including Network Rail’s (NR) layered Information Exchange (LINX) system.

- Delivered site acceptance testing (SAT) and system commissioning at Network Rail Operating Centres (ROCs).

- Supported HICSE in system design verification by establishing traceability between requirements and testing in DOORS

Asset Integrity Management

Clair Critical Cranes

Reliability and Maintainability Improvements

- Technical and commercial focal point for BP to improve reliability of BP Clair critical cranes

- Effectively managed planned maintenance routine (PMR’s) and emergent work for the assets in compliance with BP gate criteria and regulatory standards

- Formulated proposals and tenders, preparing cost estimates, reviewing design, gathering information, and conducting surveys)

- Lead failure investigations and providing detail recommendations

Rotating Machines (Port Talbot & Llanwern)

Asset Integrity Management

- Technical focal point for works area for any rotating machines issues on port Talbot and Llanwern sites.

- Facilitate the statutory and non-statutory rotating machines Inspection requirements at the Port Talbot & Llanwern plant (Fans, Pumps, Compressors, Gearboxes and Turbines)

- Assist each work area to develop plans, including Planned Maintenance Routines (PMR’s), identifying phases, determining specifications, and calculating time requirements

- Manage risks, examine vulnerabilities, implement safety measures and controls, and inspect sites to reduce incidents and hazards)

- Improve rotating machines reliability and availability by increasing MTBF.